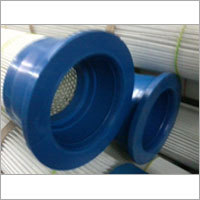

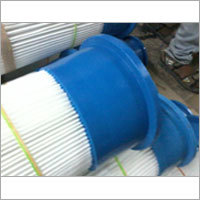

PU Moulded Pleated Filter Bag

Product Details:

- Resistance Low initial resistance

- Capacity High dust holding capacity

- Diameter 150 mm - 160 mm

- Efficiency (%) Up to 99.9%

- Type Pleated filter bag

- Material Polyurethane (PU) moulded with pleated synthetic media

- Thickness 1.8 mm - 2.0 mm

- Click to view more

PU Moulded Pleated Filter Bag Price And Quantity

- As per requirement Piece

- 1000 INR/Piece

PU Moulded Pleated Filter Bag Product Specifications

- Dust collector systems, cement plants, power plants, pharmaceuticals, food industry, metallurgy

- 1.8 mm - 2.0 mm

- Low initial resistance

- Polyurethane (PU) moulded with pleated synthetic media

- Pleated filter bag

- Up to 80C

- High dust holding capacity

- 150 mm - 160 mm

- Up to 99.9%

- <1% at 150C

PU Moulded Pleated Filter Bag Trade Information

- Cheque

- 1000 Piece Per Day

- 1 Week

- Yes

- All India

Product Description

Checkout this high quality PU Moulded Plated Bag Filter which is fabricated with utmost care and dedication by using top grade polyurethane material and modern technology. It is designed for reducing differential pressure in systems. In addition to this, our offered PU Moulded Plated Bag Filter improves airflow and increases efficiency as well as performance of the dust collector. It can be accessed in different sizes, shapes, dimensions and finishing. The said product is appreciated for its robustness and longer functional life. Furthermore, it can be easily installed and maintained.

Product details

|

Place Of Origin |

KEL |

|

No Of Pleats |

60 |

|

Length |

1000 |

|

Cage Diameter |

159 |

|

Medium Material |

Non-Woven |

|

Execution |

Sewn |

|

Color |

White |

|

Bag Type |

Mesh Filter Bag |

|

Size |

159X1000MM |

Advanced Filtration Technology

With a pleated cylindrical design and fine to micro-filtration efficiency, our filter bags significantly enhance dust capture while maintaining low resistance. This ensures improved air quality and compliance with industrial dust control standards.

Optimized for Industrial Applications

Engineered for use in dust collector systems in sectors like cement manufacturing, power generation, pharmaceuticals, and food processing, these bags feature robust polyurethane integration and are available in various sizes to accommodate diverse operational needs.

Durable and Economical

The reusable, washable synthetic media and PU-moulded caps provide leak-proof operation and a long service life. The bags are individually packed, customizable by color, and designed for easy installation as retrofits in existing systems, ensuring both cost-effectiveness and operational convenience.

FAQs of PU Moulded Pleated Filter Bag:

Q: How are PU moulded pleated filter bags installed in existing dust collectors?

A: These filter bags are specifically designed for retrofit compatibility, allowing them to be easily installed in existing dust collector systems without the need for significant modifications or special tools.Q: What benefits does the pleated design offer compared to traditional filter bags?

A: The pleated configuration amplifies the surface area by up to four times, enhancing dust retention, prolonging operational cycles, and maintaining lower pressure drops for higher air-to-cloth ratios.Q: When should the filter bags be washed or replaced?

A: These filter bags are washable and reusable, extending their service life. Cleaning frequency depends on dust load and operational conditions but should be performed when pressure drop or visibly accumulated dust reaches recommended limits.Q: Where can these filter bags be used?

A: They are suitable for a range of applications, including dust collection in cement plants, power plants, food production, pharmaceuticals, and metallurgy industries, making them versatile choices for robust dust control.Q: What process ensures the leak-proof sealing of these filter bags?

A: The bags feature PU moulded caps on both ends, which are integrally bonded to the filter media. This advanced moulding technique guarantees an air-tight seal, preventing dust bypass and leakage during operation.Q: Is there a risk of thermal shrinkage during high-temperature operations?

A: No, the filter bags are engineered to have thermal shrinkage of less than 1% at 150C, making them reliable for continuous use in environments with elevated temperatures up to 80C.Q: What is the typical lifespan and efficiency of these filter bags?

A: With up to 99.9% filtration efficiency and a design supporting high dust holding capacity, these bags offer a prolonged operational lifespan, reduced replacement frequency, and steady performance throughout their use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese